Exchange Education

GEAPS Exchange Education

Learn from industry professionals, interact with our themed Innovation Stations, or get engaged with the keynote presentation. You’re sure to learn something new to take home with you. The great slate of education at GEAPS Exchange is made possible by the Exchange Educational Programming Committee. The team of GEAPS member volunteers plan sessions in a variety of formats.

Education Plans

GEAPS Exchange offers a variety of interactive learning and professional training sessions to help you meet your educational goals. To get the most out of your experience, we recommend purchasing a full registration package, which includes access to all educational content.

The Exchange Educational Programming Committee (EPC) has designed a program tailored to your needs.

Four Comprehensive Tracks:

- Safety

- Employee Development

- Grain Operations

- Processing — NEW!

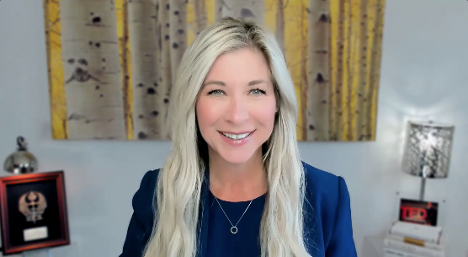

Keynote Speaker: Pamela Barnum

GEAPS Exchange 2025

Keynote Speaker

Join us Sunday morning, February 23, for an exciting keynote presentation by Pamela Barnum, a former undercover police officer and nonverbal communication expert. Her talk, “Tactical Influence,” will cover the FIRST Principles of Leadership, helping you unlock your potential as a leader. Learn how to turn adversity into growth with research-backed techniques focused on fortitude, integrity, respect, self-awareness, and tenacity. Be FIRST—join us to redefine your leadership journey!

Idea Exchange

Come see short presentations from a variety of speakers on some of the newest and innovative products and ideas to the grain industry.

What’s New?

Includes new products and services developed for grain operations during the past year. Please note, you must be an Exchange 2025 exhibitor to be considered for this program.

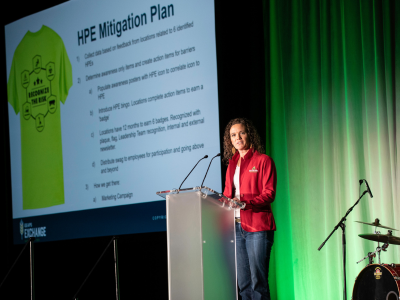

Small Changes: Big Impact

Highlights ideas grain operations managers and workers put into practice to improve safety or efficiency at their facilities or enhance environmental awareness, company culture or community involvement.

Concurrent Education Sessions

Several 45-minute to hour-long presentations are delivered by industry professionals who provide important and useful industry-specific education. Join us for topics on grain operations, safety, employee development, processing and more!

Innovation Stations

The most interactive learning opportunity at Exchange, Innovation Stations offer collaborative learning opportunities in the Expo Hall. Designed for groups of approximately 60 attendees, these sessions feature interactive presentations and equipment demonstrations in an open concept on the expo hall floor. Innovation Stations are themed in connection to the four comprehensive tracks, Processing, Safety, Employee Development and Grain Operations. Explore a variety of topics that interest you.